PAM Two-Speed

Pole – Amplitude – Modulation

PAM Two-Speed Technology

For decades, Westinghouse PAM Motors have helped industries and utilities around the world improve operating economies.

In fact, TECO-Westinghouse has more Pole Amplitude Modulation (PAM) Motor experience than all of our competitors combined.

Today, our PAM Motors continue to be an innovative solution that offers a wide range of benefits for your controlled-flow applications.

PAM Motors are durable, reliable, and cost-effective – often with a payback period of a year or less.

PAM Motors are single-winding, two-speed, squirrel cage induction motors. These motors have the ability to operate at two fixed pole speeds.

This availability of many single winding two-speed combinations gives the PAM motor a much wider range of application than that of conventional single-winding, two-speed motors, where the ratio of one speed to the other must always be two to one.

For Unequaled Dielectric Strength and Voltage Endurance

PAM Motors are AC induction machines with two predetermined speeds. Pole Amplitude Modulation offers many benefits to industrial users:

PAM Motors are an excellent economic choice for a variety for applications where a switch to the optimum speed can yield significant operating economies.

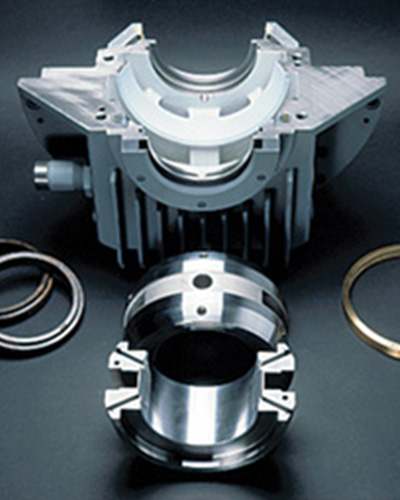

The most widely accepted speed changing device for the PAM Motor is the oil-filled, five pole, motor-operated speed-changing switch.

Scrubber Additions and Booster Fans

Scrubber Additions and Booster Fans

Today, more than ever, you must consider energy efficiencies when installing new machinery. The PAM Motor design enables you to save a significant amount of energy by switching to an optimum low speed when high-speed operation is not required.