World Series Induction Motors

Get World-Class Performance & Reliability

World Series™ Motors are the latest evolutionary step in TECO-Westinghouse AC motor technology. This top-quality line of induction motors is distinguished by high efficiencies, advanced software design capabilities, metric frame sizes and TECO-Westinghouse’s reputation for quality and reliability.

World Series™ Motors integrate the best of new motor technologies, such as computer-aided design and advanced materials, with the best of proven technologies, including rugged copper rotor construction, Thermalastic® epoxy insulation and strong fabricated frames. This unique blend of new and traditional features makes World Series™ Motors the optimal choice for heavy industry applications anywhere in the world.

Features

The following key features have enabled World Series™ Motors to reduce operating losses up to 30 percent from previous designs:

- Powerful computer design programs

Using sophisticated computer programs, TECO-Westinghouse engineers study your electrical and mechanical specifications, scan hundreds of design possibilities in minutes and select the best design for your specific requirements. The results: each motor design is optimized for the highest operating efficiency. State-of-the-art software capabilities also allow us to respond more quickly to your needs with improved outline drawings, complete quotations and accurate performance data. - Metric frame sizes

World Series™ Motors are built on a metric family of frame sizes that conform to IEC standards. As a result, more frame sizes are available than ever before, and our engineers can select optimized designs for any horsepower, RPM or voltage rating with no gaps in the entire product line. Our wider range of frame sizes also enables more efficient ventilation, which helps reduce heating and windage losses. - Improved materials

World Series™ Motors incorporate the latest advances in insulation materials. Superior insulating materials allow increased use of copper in the electrical circuit, which enhances operating efficiency.

Thermalastic® is a proprietary, integrated insulation system that impregnates the wound and connected stator with a solventless epoxy resin. Developed by Westinghouse over 40 years ago, Thermalastic® is acknowledged as the industry’s premier insulation system and is under continuous development to maintain its position as the world’s finest.

Mica is the heart of the Thermalastic® insulation system and is applied to all of the stator coils. The form-wound stator is postimpregnated with epoxy resin in a vacuum pressure tank and then transferred to an oven for polymerization. The cycle is repeated to ensure elimination of corona generating voids. The result is a stator insulation system that withstands prolonged voltage stresses, moisture, dirt, thermal cycling and chemical contaminants.

Our split-sleeve bearings are spherically seated and self aligning, thus easy to service in all field conditions. They also feature a high-tin content babbitt material and a heavy-duty, two-piece bronze oil ring. The oil ring lubrication process is easily modified for flood lubrication.

This bearing unit employs a sophisticated sealing system that is designed to prevent oil leakage along the shaft. An optional buffered seal can be provided when pressurization is required to keep hostile environments from entering the bearing.

The bearings can be inspected visually through an oil ring sight gauge and an oil level sight gauge on the housing. Bearing caps can be removed easily for bearing inspection without uncoupling the motor from the driven machine. No special tools are required for the inspection procedure.

Other types of bearings are available including:

- Deep Groove

- Angular Contact

- Spherical Roller

- Hydrodynamic

The fabricated steel frames are braced by heavy steel plate bulkheads and end plates to make the frames both laterally and torsionally stable. End brackets are reinforced to give the bearings rigid support and to minimize vibration. Located in line with the end of the frame, the bearing housing provides maximum bearing stiffness. Overall frame strength also minimizes vibration and virtually eliminates the need for realignment.

The rotors advanced design features and rugged construction begin with single-piece laminations that help prevent motor shifting and vibration.

Rotor cores are held together by heavy-duty through-bolts and end plates. Core mechanical integrity does not rely on any electrically active component. Rotor bars and end rings are copper or copper alloy. Copper is the time-proven choice for rotor construction because it provides maximum performance and reliability.

Swaged rotor bars ensure long motor life by minimizing the movement and vibration that can cause bar fatigue and failure. End rings are centrifugally cast for a void-free cross section and purity, and they are joined to the bars by high-frequency induction brazing to reduce stresses and hot spots in the joint, which can cause fatigue and failure.

- Open Dripproof Guarded

- Weather-Protected Type I

- Weather-Protected Type II

- Totally-Enclosed Water-to-Air-Cooled

- Totally-Enclosed Fan-Cooled

- Totally-Enclosed Air-to-Air Cooled

- Pipe-Ventilated

The main lead terminal box provides termination of the motor’s main power leads. Available terminal box options include lightning arresters, surge capacitors, current transformers, special grounding devices, cable or bus bar terminations, and top or bottom lead entry. Standard main lead terminal boxes are available in five sizes, ranging from 14 by 13 by 18 inches up to 36 by 36 by 36 inches, to meet any customer requirements.

A key feature of the auxiliary box is the “box within a box” system. Designed to meet National Electric Code (NEC) specifications, the auxiliary box provides safe, protected termination for all auxiliary motor devices regardless of voltage.

World Series™ Motors are used on fans, pumps, compressors, crushers, extruders, conveyors, and most types of variable and constant torque process equipment. They also can be used as induction generators for energy recovery.

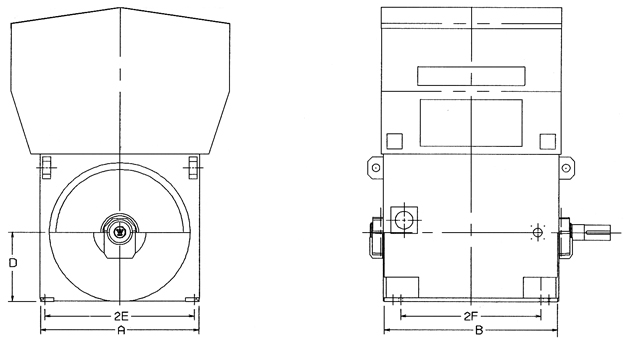

|

FRAME

|

# POLES

|

EST.WT.

|

D

|

2E

|

A

|

2F

|

B

|

D

|

2E

|

A

|

2F

|

B

|

|

LBS.

|

IN.

|

MM.

|

||||||||||

|

3505

|

4P UP

|

3200

|

13.98

|

28.0

|

31.3

|

22.0

|

32.9

|

355

|

710

|

795

|

560

|

836

|

|

3506

|

2P

|

3500

|

13.98

|

28.0

|

31.3

|

24.8

|

35.6

|

355

|

710

|

795

|

630

|

904

|

|

3507

|

4P UP

|

3800

|

13.98

|

28.0

|

31.3

|

28.0

|

38.8

|

355

|

710

|

795

|

710

|

986

|

|

3508

|

2P

|

4000

|

13.98

|

28.0

|

31.3

|

31.5

|

42.3

|

355

|

710

|

795

|

800

|

1074

|

|

3509

|

4P UP

|

4300

|

13.98

|

28.0

|

31.3

|

35.4

|

46.3

|

355

|

710

|

795

|

900

|

1176

|

|

3510

|

2P

|

4700

|

13.98

|

28.0

|

31.3

|

39.4

|

50.2

|

355

|

710

|

795

|

1000

|

1275

|

|

4008

|

4P UP

|

4800

|

15.75

|

31.5

|

35.2

|

31.5

|

42.3

|

400

|

800

|

900

|

800

|

1074

|

|

4009

|

2P

|

5100

|

15.75

|

31.5

|

35.2

|

35.4

|

46.5

|

400

|

800

|

900

|

900

|

1181

|

|

4010

|

4P UP

|

5500

|

15.75

|

31.5

|

35.2

|

39.4

|

50.2

|

400

|

800

|

900

|

1000

|

1275

|

|

4011

|

2P

|

5900

|

15.75

|

31.5

|

35.2

|

44.1

|

54.9

|

400

|

800

|

900

|

1120

|

1394

|

|

4509

|

4P UP

|

7500

|

17.72

|

35.4

|

39.1

|

35.4

|

50.2

|

450

|

900

|

995

|

900

|

1275

|

|

4510

|

2P

|

7800

|

17.72

|

35.4

|

39.1

|

39.4

|

53.9

|

450

|

900

|

995

|

1000

|

1369

|

|

4511

|

4P UP

|

8000

|

17.72

|

35.4

|

39.1

|

44.1

|

58.9

|

450

|

900

|

995

|

1120

|

1496

|

|

4512

|

2P

|

8700

|

17.72

|

35.4

|

39.1

|

49.2

|

63.7

|

450

|

900

|

995

|

1250

|

1618

|

|

5010

|

4P UP

|

9600

|

19.68

|

39.4

|

43.9

|

39.4

|

53.9

|

500

|

1000

|

1115

|

1000

|

1369

|

|

5011

|

2P

|

10500

|

19.68

|

39.4

|

43.9

|

44.1

|

58.4

|

500

|

1000

|

1115

|

1120

|

1483

|

|

5012

|

4P UP

|

10500

|

19.68

|

39.4

|

43.9

|

49.2

|

63.7

|

500

|

1000

|

1115

|

1250

|

1618

|

|

5014

|

2P

|

11000

|

19.68

|

39.4

|

43.9

|

55.1

|

69.4

|

500

|

1000

|

1115

|

1400

|

1763

|

|

5611

|

4P UP

|

14000

|

22.05

|

46.5

|

49.0

|

44.1

|

58.6

|

560

|

1180

|

1245

|

1120

|

1488

|

|

5612

|

2P

|

14500

|

22.05

|

46.5

|

49.0

|

49.2

|

63.2

|

560

|

1180

|

1245

|

1250

|

1605

|

|

5614

|

4P UP

|

15000

|

22.05

|

46.5

|

49.0

|

55.1

|

69.6

|

560

|

1180

|

1245

|

1400

|

1768

|

|

5616

|

2P

|

17000

|

22.05

|

46.5

|

49.0

|

63.0

|

77.0

|

560

|

1180

|

1245

|

1600

|

1956

|

|

6312

|

4P UP

|

18000

|

24.80

|

49.2

|

55.9

|

49.2

|

67.9

|

630

|

1250

|

1420

|

1250

|

1725

|

|

6314

|

2P

|

18500

|

24.80

|

49.2

|

55.9

|

55.1

|

74.8

|

630

|

1250

|

1420

|

1400

|

1900

|

|

6316

|

4P UP

|

19000

|

24.80

|

49.2

|

55.9

|

63.0

|

81.7

|

630

|

1250

|

1420

|

1600

|

2075

|

|

6318

|

2P

|

20000

|

24.80

|

49.2

|

55.9

|

70.9

|

89.1

|

630

|

1250

|

1420

|

1800

|

2264

|

Several Types Of Custom Motors

Induction Motors

TECO-Westinghouse Induction Motors (available in sizes from 250 hp to 30,000 hp) deliver operating efficiencies that are among the highest in the world.

Synchronous Motors

Available from 2,000 hp to 100,000 hp, TECO-Westinghouse Synchronous Motors provide superior value with proven reliability, low maintenance, and long life in demanding applications.

DC Motors

TECO-Westinghouse’s high-torque, variable speed DC machines (with ratings from 250 hp to 35,000 hp) are ideally suited for the industrial and marine markets.