Job Archives

- Motor and Drives Price Book (Effective: 09-01-25)

Stock Motors Documents

- Product Line Card (1MB)

- Product Line Card Tri-Fold (1MB)

- Fire Pump Flyer (483KB)

- Operation and Maintenance Manual for Three Phase Induction Motors - 56-449T Frames (349KB)

- Operation and Maintenance Manual for Three Phase Induction Motors - Frame Size 5000 and Larger (381KB)

- Danger and Warning in Application of Electric Induction Motor (423KB)

- AEGIS® Flyer (329KB)

- Installation and Maintenance Instructions for Three Phase Induction Motors (364KB)

- Beyond Premium Efficiency Motor Solutions (396KB)

- MAX-PM™ Permanent Magnet Motors (425KB)

Single Phase Motors

Single Phase, ODP

Single Phase, TEFC

- Farm Duty Single Phase Product Description (685KB)

- HVAC Single Phase TEFC Product Description (673KB)

Three Phase ODP Motors

Cast Iron ODP NEMA Premium

- Cast Iron ODP NEMA Premium Product Description (781KB)

- Cast Iron ODP NEMA Premium - SGR Product Description (725KB)

Oil Well Pump

ODP Rolled Steel Family

- ODP Rolled Steel ODP Flyer (532KB)

- Rolled Steel JP/JM NEMA Premium Product Description (773KB)

- Rolled Steel ODP JP/JM EPAct Product Description (773KB)

- Rolled Steel ODP NEMA Premium Efficiency Product Description (773KB)

- Rolled Steel ODP NEMA Premium Efficiency - SGR Product Description (715KB)

Three Phase TEFC Motors

2 Speed, 1 Winding, Variable Torque

Cast Iron TEFC JP/JM

MAX-E1® Family NEMA Premium Efficiency

- MAX-E1® - Inverter Duty Product Description (173KB)

- MAX-E1® C-Face, EPACT TEFC, Footed & Round Body Product Description (173KB)

- MAX-E1® Brochure (2.3MB)

MAX-E2/841® "Lite"

MAX-E2/841® Family NEMA Premium Efficiency

- MAX-E2/841™ Inverter, Severe Duty, TEFC Product Description (173KB)

- MAX-E2/841™ Footed Round Body & C-Face Product Description (173KB)

- Max-E2/ 841™ brochure (173KB)

MAX-HT™ High Torque Crusher Duty

- MAX-HT™ Low Voltage Crusher Duty - Design A Product Description (690KB)

- MAX-HT™ Low Voltage Crusher Duty - Design C Product Description (703KB)

- MAX-HT™ Medium Voltage Crusher Duty Product Description (677KB)

- MAX-HT™ brochure - Aggregate Industry solutions (600KB)

MAX-IE3 Metric

MAX-PE™

- MAX-PE™ Product Description (710KB)

- MAX-PE™ - SGR Product Description (728KB)

- MAX-PE™ brochure (347KB)

Stainless Steel Washdown, TEFC

Rolled Steel TEFC NEMA Premium Efficiency, TEFC

TEXP NEMA Premium Efficiency Explosion Proof Family

Medium Voltage ODP Motors

Global Max WPI

Global WPI

Medium Voltage TEFC Motors

Global Max TEFC

Global-XPE

Vertical Hollow Shaft Motors

MAX-VH/P Vertical Hollow Shaft WP1

- MAX-VH/P™ Vertical Hollow Shaft WPI Family Product Description (784KB)

- Vertical Hollow Shaft Brochure (1MB)

TEFC Low Voltage High Thrust with "P" Base

TEFC Medium Voltage High Thrust With "P" Base

WPI Medium Voltage High Thrust with "P" Base

Vertical Solid Shaft Motors

MAX-E2/841 TEFC SS Low Voltage Normal Thrust with "P" Base

MAX-PE TEFC SS Low Voltage Normal Thrust with "P" Base

TEFC SS Low Voltage High Thrust With "P" Base

TEFC SS Medium Voltage High Thrust With "P" Base

WPI SS Low Voltage High Thrust with "P" Base

WPI SS Medium Voltage High Thrust with "P" Base

Miscellaneous

Factory Modification Pricing

- Motor and Inverter Package flyer - Constant torque (338KB)

- Motor and Inverter Package flyer - Pump and Fan Applications (329KB)

- Factory Modifications (270KB)

Industry Related

- Mining Industry (365KB)

- Water/ Wastewater Industry (349KB)

- Cement Industry (377KB)

- Aggregate Industry solutions (600KB)

Spanish Literature

Custom Motors Documents

Product Line Card (1MB)Induction Motors

World Series™

PAM Two-Speed Motors

Wound Rotor Motor

- Wound Rotor Motor Brochure (726KB / 4 pages)

- Wound Rotor Motors for the Auto-Shredder Industry (844KB / 4 pages)

Vertical Motors

Global Series

- Global Series Brochure (705KB / 6 pages)

- Premium Efficiency Global Series Brochure (409KB / 4 pages)

- GLOBAL-MAX Standard Efficiency TEFC Product Description

- GLOBAL_MAX ODP Product Description

- Global-HD TEFC Product Description

- Global Series Product Description

- Global - Plus NEMA TEFC Product Description

Synchronous Motors & Generators

DC Motors

Miscellaneous

Industry Related

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]Vertical Capabilities

Available in sizes up to 25,000 hp, TECO-Westinghouse large Vertical motors offer many of the time-tested features found on our World Series™ line of motors. Several types of Thrust bearings are available including:- Deep Groove

- Angular Contact

- Spherical Roller

- Sleeve

- KTB Type

Wound rotor motors are an extremely versatile breed of induction motors. Featuring a rugged design, these machines provide the unique ability to gradually bring up to speed high-inertia equipment and large loads smoothly and easily. Wound rotor motors also can develop high starting torque at standstill - while maintaining low inrush. Long motor life is ensured with the use of external resistor banks or liquid rheostats that dissipate heat build-up generated during motor start-up.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" status="published" publish_date="" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="35px" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="2_3" layout="2_3" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_text columns="" column_min_width="" column_spacing="" rule_style="default" rule_size="" rule_color="" class="" id=""]- Available from 100 hp up to 10,000 hp

- Brushes selected that provide high performance under varying load conditions

- High-grade steel shaft material

- Continuously rated sliprings & brushgear

- Brush lifting & short circuiting device available

- Designed for high-starting torque with low inrush current

- Don't forget to ask us to supply you with a Liquid Rheostat on a six step Resistor Bank with your Wound Rotor order!

Applications

- Ball Mills

- Shredders

- Cement Mills

- Pumps - get varied speed

What makes the wound rotor motor a unique induction machine is its rotor. Instead of a series of rotor bars, a set of insulated rotor coils is used to accept external impedances. The rotor windings are similar to those found on a DC armature, with the coils connected together to a set of rings that make contact with carbon-composite brushes. The circuit is completed by connecting the brushes to a set of impedances such as a resistor bank or liquid rheostat. This rotor construction design allows for a varying resistance from almost short-circuit condition to an open-circuit condition with infinite external resistance. By modifying the resistance, the speed-torque characteristics can be altered. This allows for the torque to remain high, the inrush low, and the speed varied.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="yes" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="25px" margin_bottom="" padding_top="46px" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_title margin_top="" margin_bottom="70px" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" size="2" content_align="center" style_type="double solid" sep_color=""] Several Types Of Custom Motors [/fusion_title][fusion_content_boxes layout="icon-boxed" columns="3" title_size="35px" heading_size="2" title_color="#37515f" body_color="#37515f" backgroundcolor="#f2f2f2" icon="fa-accusoft fab" iconflip="" iconrotate="" iconspin="no" iconcolor="#37515f" icon_circle="yes" icon_circle_radius="" circlecolor="#ffffff" circlebordersize="1" circlebordercolor="#37515f" outercirclebordersize="0" outercirclebordercolor="" icon_size="27" icon_hover_type="" hover_accent_color="" image="" image_width="" image_height="" link_type="" button_span="" link_area="" link_target="" icon_align="left" animation_type="" animation_delay="" animation_offset="" animation_direction="left" animation_speed="0.3" margin_top="" margin_bottom="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_content_box title="Induction Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="no" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="Read More" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""] TECO-Westinghouse Induction Motors (available in sizes from 250 hp to 30,000 hp) deliver operating efficiencies that are among the highest in the world. [fusion_button link="/custom-motors/induction-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button] [/fusion_content_box][fusion_content_box title="Synchronous Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""] Available from 2,000 hp to 100,000 hp, TECO-Westinghouse Synchronous Motors provide superior value with proven reliability, low maintenance, and long life in demanding applications. [fusion_button link="/custom-motors/synchronous-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button] [/fusion_content_box][fusion_content_box title="DC Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""] TECO-Westinghouse's high-torque, variable speed DC machines (with ratings from 250 hp to 35,000 hp) are ideally suited for the industrial and marine markets. [fusion_button link="/custom-motors/dc-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button] [/fusion_content_box][/fusion_content_boxes][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]Pole - Amplitude - Modulation

PAM Two-Speed Technology For decades, Westinghouse PAM Motors have helped industries and utilities around the world improve operating economies. In fact, TECO-Westinghouse has more Pole Amplitude Modulation (PAM) Motor experience than all of our competitors combined. Today, our PAM Motors continue to be an innovative solution that offers a wide range of benefits for your controlled-flow applications. PAM Motors are durable, reliable, and cost-effective - often with a payback period of a year or less. PAM Motors are single-winding, two-speed, squirrel cage induction motors. These motors have the ability to operate at two fixed pole speeds. This availability of many single winding two-speed combinations gives the PAM motor a much wider range of application than that of conventional single-winding, two-speed motors, where the ratio of one speed to the other must always be two to one. [/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="75px" padding_right="" padding_bottom="75px" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_tabs design="classic" layout="vertical" justified="yes" backgroundcolor="" inactivecolor="" bordercolor="" icon="fa-angle-right fas" icon_position="left" icon_size="14" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_tab title="Advantages of PAM" icon=""] For Unequaled Dielectric Strength and Voltage Endurance PAM Motors are AC induction machines with two predetermined speeds. Pole Amplitude Modulation offers many benefits to industrial users: [/fusion_tab][fusion_tab title="PAM Applications" icon=""] PAM Motors are an excellent economic choice for a variety for applications where a switch to the optimum speed can yield significant operating economies. [/fusion_tab][fusion_tab title="PAM Speed Switching" icon=""] The most widely accepted speed changing device for the PAM Motor is the oil-filled, five pole, motor-operated speed-changing switch. [/fusion_tab][fusion_tab title="PAM Application Analysis - ID Fan Design Example" icon=""] Scrubber Additions and Booster Fans

Today, more than ever, you must consider energy efficiencies when installing new machinery. The PAM Motor design enables you to save a significant amount of energy by switching to an optimum low speed when high-speed operation is not required.

[/fusion_tab][/fusion_tabs][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="yes" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="#efefef" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="25px" margin_bottom="" padding_top="46px" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_title margin_top="" margin_bottom="70px" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" size="2" content_align="center" style_type="double solid" sep_color=""]

Several Types Of Custom Motors

[/fusion_title][fusion_content_boxes layout="icon-boxed" columns="3" title_size="35px" heading_size="2" title_color="#37515f" body_color="#37515f" backgroundcolor="#ffffff" icon="fa-accusoft fab" iconflip="" iconrotate="" iconspin="no" iconcolor="#37515f" icon_circle="yes" icon_circle_radius="" circlecolor="#ffffff" circlebordersize="1" circlebordercolor="#37515f" outercirclebordersize="0" outercirclebordercolor="" icon_size="27" icon_hover_type="" hover_accent_color="" image="" image_width="" image_height="" link_type="" button_span="" link_area="" link_target="" icon_align="left" animation_type="" animation_delay="" animation_offset="" animation_direction="left" animation_speed="0.3" margin_top="" margin_bottom="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_content_box title="Induction Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="no" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="Read More" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]

TECO-Westinghouse Induction Motors (available in sizes from 250 hp to 30,000 hp) deliver operating efficiencies that are among the highest in the world.

[fusion_button link="/custom-motors/induction-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button]

[/fusion_content_box][fusion_content_box title="Synchronous Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]

Available from 2,000 hp to 100,000 hp, TECO-Westinghouse Synchronous Motors provide superior value with proven reliability, low maintenance, and long life in demanding applications.

[fusion_button link="/custom-motors/synchronous-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button]

[/fusion_content_box][fusion_content_box title="DC Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]

TECO-Westinghouse's high-torque, variable speed DC machines (with ratings from 250 hp to 35,000 hp) are ideally suited for the industrial and marine markets.

[fusion_button link="/custom-motors/dc-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button]

[/fusion_content_box][/fusion_content_boxes][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Scrubber Additions and Booster Fans

Today, more than ever, you must consider energy efficiencies when installing new machinery. The PAM Motor design enables you to save a significant amount of energy by switching to an optimum low speed when high-speed operation is not required.

[/fusion_tab][/fusion_tabs][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="yes" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="#efefef" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="25px" margin_bottom="" padding_top="46px" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_title margin_top="" margin_bottom="70px" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" size="2" content_align="center" style_type="double solid" sep_color=""]

Several Types Of Custom Motors

[/fusion_title][fusion_content_boxes layout="icon-boxed" columns="3" title_size="35px" heading_size="2" title_color="#37515f" body_color="#37515f" backgroundcolor="#ffffff" icon="fa-accusoft fab" iconflip="" iconrotate="" iconspin="no" iconcolor="#37515f" icon_circle="yes" icon_circle_radius="" circlecolor="#ffffff" circlebordersize="1" circlebordercolor="#37515f" outercirclebordersize="0" outercirclebordercolor="" icon_size="27" icon_hover_type="" hover_accent_color="" image="" image_width="" image_height="" link_type="" button_span="" link_area="" link_target="" icon_align="left" animation_type="" animation_delay="" animation_offset="" animation_direction="left" animation_speed="0.3" margin_top="" margin_bottom="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_content_box title="Induction Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="no" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="Read More" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]

TECO-Westinghouse Induction Motors (available in sizes from 250 hp to 30,000 hp) deliver operating efficiencies that are among the highest in the world.

[fusion_button link="/custom-motors/induction-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button]

[/fusion_content_box][fusion_content_box title="Synchronous Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]

Available from 2,000 hp to 100,000 hp, TECO-Westinghouse Synchronous Motors provide superior value with proven reliability, low maintenance, and long life in demanding applications.

[fusion_button link="/custom-motors/synchronous-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button]

[/fusion_content_box][fusion_content_box title="DC Motors" backgroundcolor="" icon="fa-cogs fas" iconflip="" iconrotate="" iconspin="" iconcolor="" circlecolor="" circlebordersize="" circlebordercolor="" outercirclebordersize="" outercirclebordercolor="" image="" image_width="" image_height="" link="" linktext="" link_target="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]

TECO-Westinghouse's high-torque, variable speed DC machines (with ratings from 250 hp to 35,000 hp) are ideally suited for the industrial and marine markets.

[fusion_button link="/custom-motors/dc-motors/" text_transform="uppercase" title="" target="_self" link_attributes="" alignment="center" modal="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" color="default" button_gradient_top_color="" button_gradient_bottom_color="" button_gradient_top_color_hover="" button_gradient_bottom_color_hover="" accent_color="" accent_hover_color="" type="" bevel_color="" border_width="" size="" stretch="default" shape="" icon="fa-arrow-circle-right fas" icon_position="right" icon_divider="no" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]View Details[/fusion_button]

[/fusion_content_box][/fusion_content_boxes][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Petroleum / Chemical Motors

Each year brings a new and stronger challenge to the petroleum and chemical industries to be more competitive. TECO-Westinghouse recognizes motors are a significant part of the competitive solution. The petroleum and chemical industries require efficient, reliable, and life cycle cost effective motors and generators. The TECO-Westinghouse Rock 541™ Motor meets these challenges. The Rock 541™ is a motor custom designed for your specific application requirements. It combines features developed during 100+ years of experience with the latest design technology. The Rock 541™ Motor can meet or exceed the most demanding specifications. The Rock 541™ Motor can meet the lowest vibration requirements, and is available in all API 541 configurations. It provides you with state of the art technology and performance and, just as importantly, keeps you within budget. TECO-Westinghouse utilizes the latest design and management tools to produce the Rock 541™ Motor to the highest quality standards. Systems that support concurrent engineering, 3D solids modeling, and finite element analysis are employed. These engineering tools are coupled to one of the most advanced product data management programs to insure product integrity. Whatever your requirements, the TECO-Westinghouse stands ready to assist you in developing a solution. [/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="#efefef" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="45px" padding_right="" padding_bottom="45px" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_title hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" content_align="center" size="2" font_size="" line_height="" letter_spacing="" margin_top="" margin_bottom="" text_color="#607d8b" style_type="double dashed" sep_color="#d1cfcf"] Features [/fusion_title][/fusion_builder_column][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_text columns="" column_min_width="" column_spacing="" rule_style="default" rule_size="" rule_color="" class="" id=""]Features:

| Included for all Rock 541™ general purpose motors | |

|

2.1.2 |

Motors are designed for continuous operation or long periods of inactivity in petroleum / chemical plant environments. |

|

2.2.2.2 |

Motor winding brace system designed to substantially exceed 5,000 full voltage starts. |

|

2.2.6.2 |

Three cold/ two hot starting duty. |

|

2.4.5.1.2 |

Two pole motors utilize one-piece, heat treated forged steel. |

|

2.4.5.2.5 |

Connection of rotor bars to end rings through approximately 10,000HP is via induction brazing. |

|

2.4.10.5 |

Screens will be stainless steel. |

|

2.4.10.6 |

Fan systems will be non-sparking. |

|

2.4.10.7 |

Minimum stator core plate material will be C5. |

| Available for all Rock 541™ Motors | |

|

2.1.3 |

Lower than conventional noise levels. |

|

2.1.7 |

Motors are available for hazardous locations. |

|

2.4.5.1.4 |

Shaft Forgings are ultrasonically inspected. |

|

2.4.6.1.3 |

Damped unbalance response analysis. |

|

2.4.6.2.1 |

Three plane balancing of the rotor. |

|

2.4.9.5 |

Testing with contract coupling and idling adapter or mass moment simulator. |

| Some above and beyond API 541 requirement | |

|

2.3.1 |

A single VPI treatment of the stator will meet the requirements of this paragraph. The Rock 541™ will receive a minimum of two complete VPI treatments followed by a durable coat of epoxy varnish. |

|

2.4.5.2.2 |

As an alternate to copper/copper alloy, cast and fabricated aluminum rotor cages are allowed by this API paragraph. The Rock 541™ cage material will be premium copper/copper alloy only. |

|

2.4.5.2.3 |

Jointed rotor end rings are allowed at some speeds by this paragraph although it is noted that rings without circumferential joints are preferred. The end rings of Rock 541™ Motors do not contain circumferential joints at any speed. |

|

2.4.7.3 |

Conventional straight fit (liner to bearing housing) sleeve bearing liners are allowed by this paragraph. Sleeve bearing systems provided in all Rock 541™ Motors will be of the superior spherical seated self-aligning type. |

|

2.4.7.21 |

Various options are discussed for shaft/bearing seals in this API paragraph. All Rock 541™ sleeve bearing motors utilize nonmetallic, floating, self-aligning seals that exceed the requirements of this paragraph. |

- 300 hp - 3000 hp Induction Motors Available from Stock

- 3600 RPM; 2300/ 4160V; WP2 Enclosure

- Ideal for H-Pump Applications

- Suitable for Class 1, Div 2, Groups B, C & D; Temp Code T3C

- Bi-directional, F1 and F2

- Inverter Duty Design

- Anti-friction or Spherically Seated Self-Aligning, Split-Sleeve Bearings

- Air Filters & Differential Pressure Switch Included

World Series™ Motors are the latest evolutionary step in TECO-Westinghouse AC motor technology. This top-quality line of induction motors is distinguished by high efficiencies, advanced software design capabilities, metric frame sizes and TECO-Westinghouse's reputation for quality and reliability.

World Series™ Motors integrate the best of new motor technologies, such as computer-aided design and advanced materials, with the best of proven technologies, including rugged copper rotor construction, Thermalastic® epoxy insulation and strong fabricated frames. This unique blend of new and traditional features makes World Series™ Motors the optimal choice for heavy industry applications anywhere in the world.

[/fusion_text][fusion_text columns="" column_min_width="" column_spacing="" rule_style="default" rule_size="" rule_color="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""]Download World Series Brochure

[/fusion_text][fusion_text columns="" column_min_width="" column_spacing="" rule_style="default" rule_size="" rule_color="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""] [/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="45px" padding_right="" padding_bottom="45px" padding_left=""][fusion_builder_row][fusion_builder_column type="1_3" layout="1_3" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_imageframe image_id="18290" max_width="" style_type="none" stylecolor="" hover_type="none" bordersize="" bordercolor="" borderradius="" align="none" lightbox="no" gallery_id="" lightbox_image="" alt="" link="" linktarget="_self" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset=""]https://www.tecowestinghouse.com/wp-content/uploads/2018/09/Motor-Repair.jpg[/fusion_imageframe][/fusion_builder_column][fusion_builder_column type="2_3" layout="1_2" last="no" spacing="yes" center_content="no" hide_on_mobile="no" background_color="" background_image="" background_repeat="no-repeat" background_position="left top" border_size="0px" border_color="" border_style="" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="" animation_speed="0.1" class="" id="" min_height="" hover_type="none" link="" border_position="all"][fusion_title margin_top="" margin_bottom="35px" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" size="3" content_align="left" style_type="double dashed" sep_color="#c6c4c4"] Features [/fusion_title][fusion_accordion type="" boxed_mode="" border_size="" border_color="" background_color="" hover_color="" divider_line="" title_font_size="" icon_size="" icon_color="" icon_boxed_mode="" icon_box_color="" icon_alignment="" toggle_hover_accent_color="#137cad" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_toggle title="Enhanced Efficiencies for Greater Savings" open="no"]Operating efficiencies are vitally important to the bottom-line needs of industry. You may save hundreds of thousands of dollars over the life of a motor by careful evaluation of the operating efficiency. That’s why World Series™ Motors are designed to deliver operating efficiencies that are among the highest in the world... [/fusion_toggle][fusion_toggle title="Thermalastic® Epoxy Insulation System" open="no"]For Unequaled Dielectric Strength and Voltage Endurance Thermalastic® is a proprietary, integrated insulation system that impregnates the wound and connected stator with a solventless epoxy resin. Developed by Westinghouse over 40 years ago, Thermalastic® is acknowledged as the industry’s premier insulation system and is under continuous development to maintain its position as the world’s finest. [/fusion_toggle][fusion_toggle title="Advanced Bearing System for Reliable Performance" open="no"]The bearing system used in World Series™ Motors has been designed and engineered for continuous, reliable performance and easy maintenance. Both anti-friction and split-sleeve bearings are offered. When required, bearing insulation can be added to either bearing type. [/fusion_toggle][fusion_toggle title="Rugged Box Frame Construction for Strength and Reliability" open="no"]World Series™ Motors use box frame construction to provide frames that have the mechanical strength and stability to assure years of dependable, economical performance. [/fusion_toggle][fusion_toggle title="Heavy-Duty Rotor Construction for Dependable Service" open="no"]TECO-Westinghouse induction motor rotors are recognized as the most reliable in the industry, and their high performance standards are a hallmark of the World Series™ Motors. [/fusion_toggle][fusion_toggle title="Available NEMA Enclosures" open="no"]World Series™ Motors are offered in a complete range of NEMA enclosures to meet the toughest demands of industry. IEC enclosures can also be supplied. Available NEMA enclosures include the following configurations: [/fusion_toggle][fusion_toggle title="Terminal Boxes" open="no"]World Series™ Motors feature main lead terminal and auxiliary boxes constructed of 12-guage steel. Each terminal box is gasketed for air-tight, dust-free and weatherproof protection of terminal leads. Available for F1 or F2 locations, terminal boxes can be modified to include any customer terminations and accessory devices. [/fusion_toggle][fusion_toggle title="Applications" open="no"]World Series™ Motors are custom-designed to each customer’s specific application. Because of their design versatility and high operating efficiencies, the World Series™ Motors are the logical choice for a multitude of industries, including pulp and paper, electric utility, marine, water and waste water treatment, chemical and petrochemical, steel, mining, air conditioning and air separation applications. [/fusion_toggle][fusion_toggle title="Dimensions" open="no"]

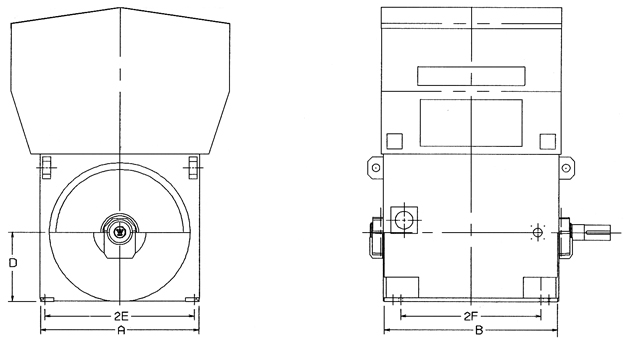

|

FRAME |

# POLES |

EST.WT. |

D |

2E |

A |

2F |

B |

D |

2E |

A |

2F |

B |

|

LBS. |

IN. |

MM. |

||||||||||

|

3505 |

4P UP |

3200 |

13.98 |

28.0 |

31.3 |

22.0 |

32.9 |

355 |

710 |

795 |

560 |

836 |

|

3506 |

2P |

3500 |

13.98 |

28.0 |

31.3 |

24.8 |

35.6 |

355 |

710 |

795 |

630 |

904 |

|

3507 |

4P UP |

3800 |

13.98 |

28.0 |

31.3 |

28.0 |

38.8 |

355 |

710 |

795 |

710 |

986 |

|

3508 |

2P |

4000 |

13.98 |

28.0 |

31.3 |

31.5 |

42.3 |

355 |

710 |

795 |

800 |

1074 |

|

3509 |

4P UP |

4300 |

13.98 |

28.0 |

31.3 |

35.4 |

46.3 |

355 |

710 |

795 |

900 |

1176 |

|

3510 |

2P |

4700 |

13.98 |

28.0 |

31.3 |

39.4 |

50.2 |

355 |

710 |

795 |

1000 |

1275 |

|

4008 |

4P UP |

4800 |

15.75 |

31.5 |

35.2 |

31.5 |

42.3 |

400 |

800 |

900 |

800 |

1074 |

|

4009 |

2P |

5100 |

15.75 |

31.5 |

35.2 |

35.4 |

46.5 |

400 |

800 |

900 |

900 |

1181 |

|

4010 |

4P UP |

5500 |

15.75 |

31.5 |

35.2 |

39.4 |

50.2 |

400 |

800 |

900 |

1000 |

1275 |

|

4011 |

2P |

5900 |

15.75 |

31.5 |

35.2 |

44.1 |

54.9 |

400 |

800 |

900 |

1120 |

1394 |

|

4509 |

4P UP |

7500 |

17.72 |

35.4 |

39.1 |

35.4 |

50.2 |

450 |

900 |

995 |

900 |

1275 |

|

4510 |

2P |

7800 |

17.72 |

35.4 |

39.1 |

39.4 |

53.9 |

450 |

900 |

995 |

1000 |

1369 |

|

4511 |

4P UP |

8000 |

17.72 |

35.4 |

39.1 |

44.1 |

58.9 |

450 |

900 |

995 |

1120 |

1496 |

|

4512 |

2P |

8700 |

17.72 |

35.4 |

39.1 |

49.2 |

63.7 |

450 |

900 |

995 |

1250 |

1618 |

|

5010 |

4P UP |

9600 |

19.68 |

39.4 |

43.9 |

39.4 |

53.9 |

500 |

1000 |

1115 |

1000 |

1369 |

|

5011 |

2P |

10500 |

19.68 |

39.4 |

43.9 |

44.1 |

58.4 |

500 |

1000 |

1115 |

1120 |

1483 |

|

5012 |

4P UP |

10500 |

19.68 |

39.4 |

43.9 |

49.2 |

63.7 |

500 |

1000 |

1115 |

1250 |

1618 |

|

5014 |

2P |

11000 |

19.68 |

39.4 |

43.9 |

55.1 |

69.4 |

500 |

1000 |

1115 |

1400 |

1763 |

|

5611 |

4P UP |

14000 |

22.05 |

46.5 |

49.0 |

44.1 |

58.6 |

560 |

1180 |

1245 |

1120 |

1488 |

|

5612 |

2P |

14500 |

22.05 |

46.5 |

49.0 |

49.2 |

63.2 |

560 |

1180 |

1245 |

1250 |

1605 |

|

5614 |

4P UP |

15000 |

22.05 |

46.5 |

49.0 |

55.1 |

69.6 |

560 |

1180 |

1245 |

1400 |

1768 |

|

5616 |

2P |

17000 |

22.05 |

46.5 |

49.0 |

63.0 |

77.0 |

560 |

1180 |

1245 |

1600 |

1956 |

|

6312 |

4P UP |

18000 |

24.80 |

49.2 |

55.9 |

49.2 |

67.9 |

630 |

1250 |

1420 |

1250 |

1725 |

|

6314 |

2P |

18500 |

24.80 |

49.2 |

55.9 |

55.1 |

74.8 |

630 |

1250 |

1420 |

1400 |

1900 |

|

6316 |

4P UP |

19000 |

24.80 |

49.2 |

55.9 |

63.0 |

81.7 |

630 |

1250 |

1420 |

1600 |

2075 |

|

6318 |

2P |

20000 |

24.80 |

49.2 |

55.9 |

70.9 |

89.1 |

630 |

1250 |

1420 |

1800 |

2264 |

Direct from Round Rock, Texas

TECO-Westinghouse Direct Current (DC) motors are ideally suited to a multitude of industrial and marine applications in which high torque and variable speeds are required. These applications include ship propulsion, mine hoists and steel rolling mills. They also drive many other types of industrial equipment such as fan drives, Banbury mixers and extruders. To meet the needs of a broad range of applications, our rugged DC motors are available in sizes ranging from 22-inch to 12-foot armature diameters, with available power ratings from 250 hp to over 35,000 hp. Quality Features / Time-Tested Performance- High efficiency designs reduce life cycle costs.

- Advanced insulation systems protect against moisture, dust, heat, and contamination.

- Critical area electrostatic coating provides long creepage paths.

- High temperature rise capabilities offer cost economies.

- V-ring, "balanced-spring", commutator ensures concentricity and prevents distortion.

- High fatigue strength risers increase reliability.

- Lift-away end covers improve accessibility.

- Ruggedly built spiders smoothly transmit torque.

- Integral ventilation package available to continuously circulate cooling air.

- Keyless coupling eliminate inherent disadvantages of key ways.

- Rigid-support, accurately machined bedplates ensure stability.

- Armature wedges and banding assure excellent coil ventilation & accessibility.

- Heavy-duty stators offer outstanding reliability.

- Bearings with self-aligning, spherical seats provide excellent heat transfer.

- Rear mounted cross connections provide accessibility and mechanical stability.

- Full laminated coils reduce eddy current loss.

- Removable shafts available for both continuous and rapid reversing operation.

- Wound-on-pole shunt fields assure excellent heat transfer.

- Sturdy frames provide optimum flux carrying configurations.

- Rear to front ventilation system provides maximum heat dissipation.

More Information

[/fusion_title][fusion_checklist icon="" iconcolor="" circle="" circlecolor="" size="17px" divider="" divider_color="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_li_item icon=""]Request a Quote[/fusion_li_item][fusion_li_item icon="fa-file-pdf far"]DC Brochure[/fusion_li_item][/fusion_checklist][/fusion_builder_column_inner][/fusion_builder_row_inner][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="yes" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_title margin_top="" margin_bottom="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" size="1" content_align="left" style_type="default" sep_color=""] Features: [/fusion_title][fusion_accordion type="" boxed_mode="" border_size="1" border_color="" background_color="" hover_color="" divider_line="" title_font_size="" icon_size="" icon_color="" icon_boxed_mode="" icon_box_color="" icon_alignment="" toggle_hover_accent_color="#137cad" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_toggle title="Applications" open="no"] Rolling Mill Motors Used in the steel and aluminum industries, rolling mill motors generally operate at low speeds and are designed for constant torque with a speed range of up to four to one. Some applications include continuous cold mills, continuous hot strip mills, and reversing hot mills. [/fusion_toggle][fusion_toggle title="Read More Key Stator / Armature Components" open="no"] Stator Construction TECO-Westinghouse stators are designed and built to provide exceptional performance and outstanding reliability. The main poles and commutating poles are all laminated to assure quick response to speed and load changes. Our full-length commutating poles lower the reactance voltage and compensating windings provide proper compensation for armature reaction. Stator end connection joints are TIG-welded together for maximum strength. Compensating winding straps are individually bolted at the centerline split to allow quick removal of the top half of the stator. All stator electrical conductors are made from copper. [/fusion_toggle][fusion_toggle title="Thermalastic® Insulation" open="no"] Used in thousands of TECO-Westinghouse motors in the field since its introduction, Thermalastic® insulation has proven to be the industry's premier insulation system. Due to its unique structure, the dielectric material is locked in a stable elastic bond to form a barrier that withstands prolonged voltage stresses, moisture, abrasion, dirt and thermal cycling. Thermalastic® insulation is chemically stable in the most severe environments, making it well suited to the most rigorous applications of our DC motors. In less demanding DC applications, other insulation systems may be utilized [/fusion_toggle][fusion_toggle title="Digard® Insulation" open="no"] Digard® is a specially-developed epoxy powder used in the riser insulation system. The electro statically applied powder is preferentially attracted to the riser edges. As a result, the insulating material is actually thicker at critical edge areas. This coating is applied to the armature when hot, allowing the powder to melt and flow. This smooth, void-free surface provides long creepage paths and prevents carbon dust from adhering, thus eliminating the major cause of low insulation resistance in DC machines. [/fusion_toggle][fusion_toggle title="Arch-Bound, V-Ring,'Balanced-Spring' Commutators" open="no"] Our V-ring commutators feature true arch-bound construction with fully centered "floating" bars to ensure concentricity and eliminate distortion. The major "spring-like" commutator components, such as the V-rings, copper overhangs and thru-studs are specifically designed to assure uniform radial motion of the commutator bars at operating speed and temperature. This "balanced-spring" feature provides a smooth, brush riding surface under thermal and centrifugal forces thus assuring maximum brush life. Longitudinal thru-studs permit a convenient check for commutator tightness. All commutators are fully seasoned at rotational speeds. [/fusion_toggle][fusion_toggle title="Self-Aligning Bearings" open="no"] The self-aligning, spherical seat bearings utilized on TECO-Westinghouse DC motors are designed and engineered for continuous, reliable performance and easy maintenance. The bearing caps are removable and the bearing is split for easy inspection. The bearing units provide excellent heat transfer from babbitt to oil and to the pedestal. Oil ring lubrication is simple, effective and trouble free. When required, these bearings are also offered with internal disc lubrication or forced lubrication. Where special low friction starting is required or for continuous operation at very low speeds, hydrostatic lift can be supplied. A number of surface configurations are available depending on the magnitude of the thrust force. [/fusion_toggle][fusion_toggle title="TIG Welded Connections" open="no"] Tungsten inert gas (TIG) welding is used to connect the armature coils to the commutator risers and the inner pole and pole face winding connections. This method of joining copper to copper produces a connection that has high strength, is low in resistance and is free of oxides, thereby assuring electrical, mechanical and thermal superiority. [/fusion_toggle][fusion_toggle title="Keyless Couplings" open="no"] TECO-Westinghouse pioneered the use of keyless couplings thus eliminated the problem of slippage under heavy torque, which is often associated with key-type couplings. Our keyless couplings are shrunk on the shaft with high interference fits that provide a strong bond. Special fittings and grooves allow the couplings to be removed and even installed using hydraulic pressure. Key-type couplings can be designed where specific applications call for them. [/fusion_toggle][fusion_toggle title="Sturdy Frame Construction" open="no"] Our large DC motors feature laminated steel frames for faster response and exceptional electrical performance. The commutation flux more easily follows the rapid changes in load current, resulting in better commutator. The lower frame time constant allows voltage changes to respond more quickly to regulator demands. [/fusion_toggle][fusion_toggle title="Multiple Armatures" open="no"] Depending on your specific application, the TECO-Westinghouse can provide double, triple, even quadruple armature motor designed to deliver the required torque while minimizing the inertia of the drive-train. A special two bearing double armature is available in some sizes which offers low inertia while being very compact. [/fusion_toggle][/fusion_accordion][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="3_5" layout="2_3" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" margin_top="" margin_bottom="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_title margin_top="" margin_bottom="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" size="1" content_align="left" style_type="default" sep_color=""]Cutaway of DC Motor[/fusion_title][fusion_text columns="" column_min_width="" column_spacing="" rule_style="default" rule_size="" rule_color="" class="" id=""]- Coupling

- Spider

- Armature Laminations

- Armature Cross-Connections

- Main Pole

- Main Field Winding

- Lift-away End Cover

- Frame

- Compensating Winding

- Frame Brush Rigging Arms

- Armature Coils

- Riser

- Brush Holder Brackets

- Brushes

- Commutator Bar

- Commutator Spider

- Shaft

- Bearing

- Spherical Seat

- Oil Rings

- Oil Reservoir

- Pedestal

- Bedplate

- First electric motors in an American steel mill (1891)

- First electric drive for main rolls

- First reversing mill drive

- First large twin-motor reversing mill drive

- First application of separately excited shunt-wound DC motors

- First Ward Leonard dragline systems

- First vertical swing motors

- First laminated frame generators

- First dual circuit generator system

Full Speed Ahead

TECO-Westinghouse synchronous motors and generators provide superior value in terms of proven reliability, low maintenance performance and long life in any application. Our synchronous machines offer numerous benefits including:

- Constant-speed operation

- High efficiency ratings

- Low inrush currents

- Leading power factor (for corrective KVA capability)

The rotor construction starts with a high strength alloy steel shaft forging that is precision machined, ground and finished to our exact tolerances. Next the rotor spider is constructed from massive steel laminations and machined to mate with the shaft to form the rotor core assembly. Dovetail slots are then milled into the spider to accept the dovetailed pole pieces that are secured in place by tapered keys. Dovetail pole construction (pictured below) ensures a secure attachment to the shaft and spider.

Rotor poles are stacked from thin laminations bolted together to form the pole pieces. Field coils are edge-bent and strap wound, then insulated with a custom-designed thermosetting turn insulation system before being installed onto the rotor poles. Coils are staggered to allow for efficient heat transfer and are solidly braced at the final assembly stage.

Amortisseur windings use copper/copper alloy damper bars and segments. A shaped copper interconnect between adjacent poles alleviates thermal stresses which occur during starting.

The rotor construction starts with a high strength alloy steel shaft forging that is precision machined, ground and finished to our exact tolerances. Next the rotor spider is constructed from massive steel laminations and machined to mate with the shaft to form the rotor core assembly. Dovetail slots are then milled into the spider to accept the dovetailed pole pieces that are secured in place by tapered keys. Dovetail pole construction (pictured below) ensures a secure attachment to the shaft and spider.

Rotor poles are stacked from thin laminations bolted together to form the pole pieces. Field coils are edge-bent and strap wound, then insulated with a custom-designed thermosetting turn insulation system before being installed onto the rotor poles. Coils are staggered to allow for efficient heat transfer and are solidly braced at the final assembly stage.

Amortisseur windings use copper/copper alloy damper bars and segments. A shaped copper interconnect between adjacent poles alleviates thermal stresses which occur during starting.

The TECO-Westinghouse brushless excitation system consists of a field discharge resistor, diodes, SCR’s a gating module and a synchronizing module. The discharge resistor is shunted across the motor field during starting. At the proper slip and phase angle, the resistor is removed automatically from the field circuit and DC current is applied to the field to pull the motor into synchronism.

The key to the Pulse/ SYN system is the synchronizing module. This module has two separate functions. The first function is phase angle synchronization. The module monitors rotor speed (by frequency of induced field voltage) and rotor phase angle (by phase angle of induced voltage). When the speed and phase angle are such as to cause minimum disturbance to the supply system the field voltage is applied and the motor "pulls-in" to synchronization.

The second function of the synchronizing module is to handle the occurrence of "post-synchronization." This is when the motor synchronizes by reluctance before the field voltage is applied. The module monitors the rotor speed and excitations voltage. When the frequency of induced field voltage is zero for a predetermined time and excitation voltage is available, the field voltage is applied to the motor field. This action places the rotor in proper phase position and synchronization.

The TECO-Westinghouse brushless excitation system consists of a field discharge resistor, diodes, SCR’s a gating module and a synchronizing module. The discharge resistor is shunted across the motor field during starting. At the proper slip and phase angle, the resistor is removed automatically from the field circuit and DC current is applied to the field to pull the motor into synchronism.

The key to the Pulse/ SYN system is the synchronizing module. This module has two separate functions. The first function is phase angle synchronization. The module monitors rotor speed (by frequency of induced field voltage) and rotor phase angle (by phase angle of induced voltage). When the speed and phase angle are such as to cause minimum disturbance to the supply system the field voltage is applied and the motor "pulls-in" to synchronization.

The second function of the synchronizing module is to handle the occurrence of "post-synchronization." This is when the motor synchronizes by reluctance before the field voltage is applied. The module monitors the rotor speed and excitations voltage. When the frequency of induced field voltage is zero for a predetermined time and excitation voltage is available, the field voltage is applied to the motor field. This action places the rotor in proper phase position and synchronization.